Mixing Granular Material Gravimetric Batch Blender In Extrusion

1.Products Introduction

WalthMac WBB Series Gravimetric Batch Blender under WalthMac is a weighing and mixing

system,setting the proportion of each raw material then the machine

will work automatically.

2.Main Structure

- Air Source Processor works as converting compressed air into

kinetic energy

- The solenoid valve works as providing kinetic energy

- The display control unit works as displaying the cutting accuracy

of each component

- The cylinder works as controlling the knife valve for each silo's

feeding

- Data Acquisition Control Unit works as controlling and collects the

operational information of the entire machine

3.Parameter

| Components | Up to 8 components |

| Weighing resolution | 1/4000000 |

| Control units | Micro operation,adaption algorithm |

| Communication interface | USB,Ethernet port |

| Mixing chamber sensor | Weighing sensor |

4.Features

- Adopts the weighing module of 1/4 million weighing resolution

- Not only improves the quality of products, but also saves precious

raw material costs

- key components are purchased from world-class supplier

- Stablely operating

5.Benefits

- Maxiumn output is 1600kg/hr (for this type)

- Feeding error not more than 0.1%

- Formula change in real time

- Remain materials quick auto-clean

6.Applications Scope

Gravimetric Batch Blender is suitable for plastic

film,cables,plastic modification industires.Our machine can blend 2/4/6/8 components once a time,we will

recommend the suitable type for customers after receiving the

specific of their raw materials.

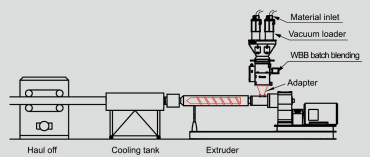

7.Way of installation

Installing Gravimetric Batch Blender with an adapter on the

extruder ,this installation needs to convey raw materials once from

storage to system by vacuum loader.

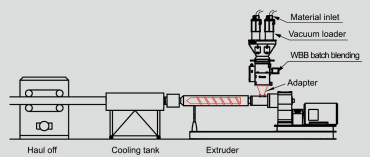

Installing the Gravimetric Batch Blender on the floor with a

platform,there will convey raw materials twice ,first step is from

storage to system by vacuum loaders,second step is from the bottom

hopper of Gravimetric Batch Blender to vacuum loader upon the

material hopper which set on the extruder.

8.On-sight Application

Application pictures are all sent from our customers who have

cooperated with us for a long time.

9.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise pursuing "product is art". Realizing highly automatic of

smart workshop is a trend of future factory development.

Achieving a highly intelligent workshop in the future is the trend

of factories in the future, and it is also the parent goal for

Worth to strive for. Worth products focus on helping users achieve

automation throughout the production process, from improving

product quality and saving raw materials to reducing the dependence

on labor throughout the process.

Since extablished in 2009,in these 14 years, we have participated

in plastic and rubber exhibitions in China and other countries such

as Vietnam,Thailand,America,England etc. We are cooperating with

over 800 companies like DEMUKA,GSM etc, and establishing long-term

cooperative relationships with them.

All products are packed safely before delivery to ensure that the

goods will not be damaged, scratched and other conditions during

transportation.We offer many modes of transportation including sea

and air, international mainstream freight companies are supported.

10.FAQ

Q1:Are you manufacturer or trade company?

A: We are manufacturer who design and sell own machines

Q2:What's the term of payment?

A: Usually via T/T and we need prepayment.

Q3:What's the term of delivery?

A: You can choose EXW,FOB,CFR,CIF.

Q4:Will you test the machine before delivery?

A:Yes,all machines will be test before packaging.